Purchase Accuracy: Reveal Unique Bargains on High-Quality Star Screen Tools

Purchase Accuracy: Reveal Unique Bargains on High-Quality Star Screen Tools

Blog Article

How Disc Screens Revolutionize Recycling Tools for Better Results

The Functionality of Disc Screens

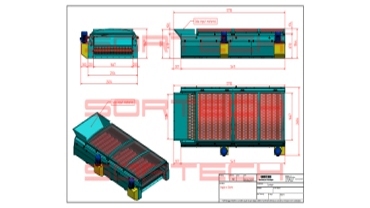

Disc screens are an important component of recycling devices, effectively dividing materials based on shapes and size to enhance the general recycling process. These displays are composed of a collection of revolving discs with particular openings that allow smaller sized materials to go through while larger products are maintained. The discs are positioned at an angle, permitting gravity to help in the splitting up procedure.

The performance of disc screens lies in their capability to precisely and effectively different materials, boosting the high quality of recycled products. As the discs revolve, the materials are fed onto the display, and the smaller sized fragments fall via the openings. This separation procedure guarantees that materials of various dimensions are sorted into distinct streams, enabling additional processing or straight reuse.

Advantages of Utilizing Disc Screens in Recycling

Among the essential advantages of incorporating disc displays into recycling equipment is their capacity to substantially boost the effectiveness and performance of the reusing process (star screen). Disc screens supply numerous benefits that make them an important component in modern-day reusing centers

Firstly, disc displays are highly efficient in separating products of different dimensions. The turning discs with exact spacing permit smaller sized fragments to fail, while larger products are conveyed ahead. This causes a more regular and exact sorting of recyclables, minimizing the requirement for manual sorting and boosting total productivity.

Secondly, disc screens are developed to handle a wide range of materials, including bulky and unpleasant waste. Their robust building and sturdy products make certain that they can stand up to the extreme conditions of the recycling process, minimizing downtime and maintenance expenses.

Additionally, disc displays have a high throughput capacity, enabling them to process big volumes of waste in a shorter quantity of time. This not only increases performance however additionally allows reusing facilities to satisfy the expanding demand for recycled materials.

An additional benefit of disc displays is their capability to minimize contamination in the last sorted materials. By effectively removing unwanted materials, such as plastics or paper, disc screens aid generate higher-quality recyclables, which in turn raises their market value.

Exactly How Disc Screens Improve Performance in Sorting

Incorporating disc screens into recycling tools not just uses countless advantages however it additionally dramatically improves the efficiency of the sorting process. Disc screens are developed to separate products based on their shape, density, and size, resulting in an extra efficient and precise sorting procedure.

Among the key methods which disc screens enhance performance is with their capability to take care of a high quantity of product. With their revolving discs, these displays can rapidly process big amounts of recyclables, minimizing the time and effort needed for sorting. This increased throughput allows recycling facilities to kind and procedure materials at a quicker price, inevitably raising general productivity.

Additionally, disc displays improve performance by efficiently separating various kinds of materials. The discs on the display have actually tactically positioned openings that enable smaller sized materials to travel through while bigger materials are redirected to an additional conveyor or arranging system. This makes certain that each product stream is correctly arranged, decreasing the threat of contamination and enhancing the high quality of the recycled materials.

Moreover, disc screens are equipped with innovative technology that enables specific material splitting up. By adjusting the speed, angle, and spacing of the discs, drivers can personalize the sorting process to meet details requirements. This degree of control makes certain that products are accurately arranged, maximizing the healing of important sources and lessening waste.

Enhancing the Quality of Recycled Materials With Disc Screens

With the assimilation of disc displays into reusing equipment, the quality of recycled products can be significantly enhanced. Disc displays are ingenious makers that play an essential function in the reusing procedure by efficiently separating various sorts of products. These displays consist of multiple turning discs with particular opening dimensions, allowing smaller bits to fail while bigger materials proceed along the conveyor belt. By utilizing disc screens, recyclers can attain a higher degree of purity in their final result.

One of the essential benefits of disc screens is their capability to eliminate impurities such as plastic movie, paper, and other non-recyclable materials. The turning learn this here now discs efficiently different these pollutants from the recyclable materials, leading to a cleaner and purer end item. This not only enhances the overall top quality of recycled products yet likewise minimizes the risk of contamination in downstream procedures.

Additionally, disc displays can boost the top quality of recycled products by successfully dividing different sorts of recyclables based upon their shapes and size. This enables recyclers to create products with constant bit dimensions, which are in high demand by suppliers. Consistency in particle size improves the efficiency of recycled materials in various applications, such as plastic molding and paper production.

The Future of Recycling Devices: Disc Screens

The continued development of recycling tools modern technology is paving the method for the future of disc displays. These innovative devices are readied to change the recycling industry by boosting performance and boosting the high quality of recycled materials.

One of the vital growths in disc screen innovation is the assimilation of expert system (AI) and artificial intelligence formulas. These innovations make it possible for disc displays to adapt and optimize their efficiency based upon real-time data. By examining the structure and characteristics of incoming products, disc screens can readjust their settings to achieve the best feasible splitting up and sorting outcomes.

An additional area of emphasis for the future of disc screens is their ability to manage a broader series of products. Traditional disc screens were primarily designed for sorting paper, cardboard, and plastics. With the increasing demand for reusing various types of waste, there is a need for disc screens that can successfully take care of products such as glass, metals, and electronic waste.

Additionally, the future of disc displays hinges on their ability to find more reduce maintenance and operational prices. Makers are investing in r & d to create even more resilient and resilient displays that need marginal upkeep. Additionally, advancements in automation and remote tracking innovations will certainly make it possible for drivers to remotely keep an eye on more and control disc displays, minimizing the demand for on-site employees.

Verdict

Finally, disc displays have revolutionized recycling equipment by enhancing efficiency in boosting the quality and sorting of recycled products. Their functionality permits reliable separation of different materials, causing far better outcomes and enhanced performance in the reusing procedure. As the future of reusing devices, disc screens offer promising advancements in the area, leading the way for a much more lasting and effective recycling industry.

Disc screens are an indispensable element of recycling equipment, successfully separating materials based on dimension and form to enhance the general recycling procedure (star screen). These displays consist of a series of turning discs with details openings that allow smaller products to pass via while larger products are preserved. The discs on the screen have tactically put openings that allow smaller sized materials to pass via while larger materials are redirected to one more conveyor or sorting system. Disc displays are ingenious equipments that play a critical role in the recycling process by efficiently dividing different kinds of products.In conclusion, disc screens have actually changed reusing equipment by improving efficiency in sorting and enhancing the high quality of recycled materials

Report this page